Fire-Resistant Duct Inspection Services

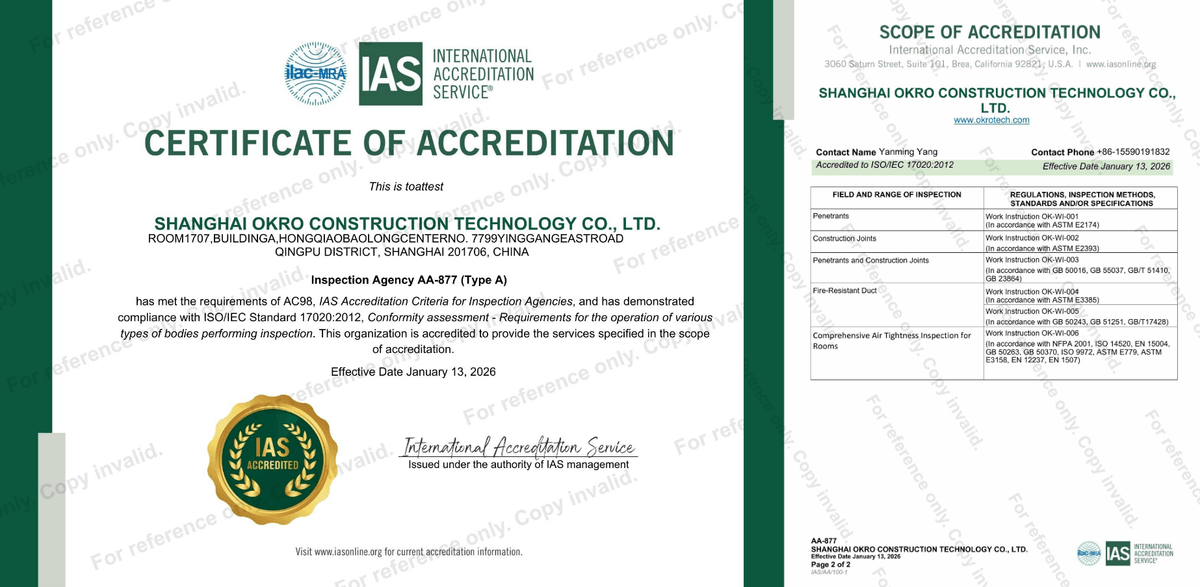

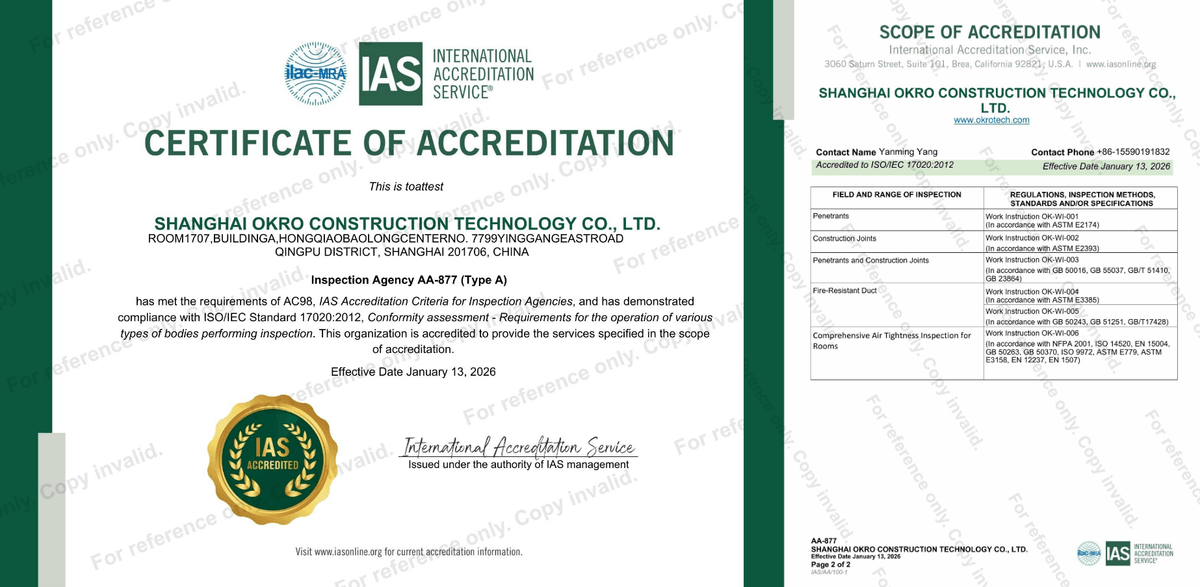

Shanghai OKRO Construction Technology Co., Ltd. provides professional on-site inspection services for fire-resistant ductwork, ensuring building ventilation, grease, and hazardous exhaust systems maintain their fire-resistance integrity under fire conditions, effectively preventing the spread of smoke and flame to maximize occupant and property protection. Services are conducted in accordance with ISO/IEC 17020 and recognized under IAS AC98 accreditation, with all inspectors authorized under international standards.

Reference Standards

- ASTM E3385: Standard Practice for On-site Inspection of Fire Resistive Duct Systems

- UL 2221: Standard for Tests of Fire Resistive Grease Duct Enclosure Assemblies

- ASTM E2336: Test Methods for Fire Resistive Grease Duct Enclosure Systems

- ASTM E2816: Test Methods for Fire Resistive Metallic HVAC Duct Systems

- ISO 6944-1: Fire Containment – Ventilation Ducts

- GB 50243-2016: Code of Acceptance for Construction Quality of Ventilation and Air Conditioning Works

- GB 51251-2017: Technical Standard for Smoke Management Systems in Buildings

GB/T 17428-2009: Fire-Resistance Test Methods ofVentilation Ducts

Scope of Inspection

- Grease Duct Systems: Assess compliance of commercial kitchen exhaust duct systems with fire-protection requirements

- HVAC Duct Systems: Verify metallic duct construction, fire compartmentation, and installation quality

- Hazardous Exhaust Systems: Inspect ventilation ducts in chemical, laboratory, and other high-risk industrial settings

Inspection Process

1Preparation Stage

- Review inspection documents, construction drawings, listing certificates, and test reports

- Verify materials (model, thickness, fireproof coating, reinforcements, manufacturer, certification)

- Prepare calibrated measurement tools (coating thickness gauge, calipers, steel tape, etc.)

- Develop the on-site inspection plan includingsafety measures

2Site Inspection

Key Focus Areas

- Duct Construction: Material, specification, seam type, airflow ratings as per listing

- Joints & Connections: Flange types, spacing, assembly methods

- Reinforcements: Rod size, interval, correct installation

- Fire Protection System: Rated performance hours, coating thickness, material density, joint sealing

- Supports & Hangers: Type, size, and interval, per listing and codes

- Access Doors (if applicable): Structure andfire-protection methods

3Reporting and

Re-Inspection

- Non-conformities and results recorded using a dedicated checklist and marked onsite

- Detailed inspection report issued outlining deficiencies and required corrective measures

- Upon rectification, follow-up inspectionconducted; records and acceptance documentation updated accordingly

4Deliverables

- Work Instruction for Fire-Resistant Duct Inspection

- Inspection Checklist

- Inspection Report

Key Advantages

- Full compliance with both national (GB) and international standards with certified authority

- Traceable inspection process: documentation, images, and reports integrated and archived

- Systematic risk mitigation support for owners, contractors, and insurers, facilitating prompt identification and remediation of potential hazards

OKRO Construction Technology’s professional firestop inspection & fire-resistant duct inspection services provide comprehensive safety protection for your building, ensuring compliance and extending the lifespan of your fire protection system. We are your trusted partner in fire safety.