The tragic fire at Hong Kong’s Hung Fuk Estate once again revealed a painful truth: the greatest threat to life is often not the visible flames, but the toxic smoke that races through wall penetrations, ducts, and hidden gaps. Fire can be extinguished—but once these “invisible pathways” breach a fire compartment, evacuation time collapses and casualties rise sharply.

In modern buildings, mechanical, electrical, and ventilation systems intersect across every floor. Each penetration through a wall or slab must be sealed with certified firestop materials. These firestop systems—though frequently overlooked—form the most critical barrier in passive fire protection. Ensuring the reliability of this life-saving defense requires far more than visual judgment. Independent third-party inspection, aligned with international standards, is essential to make safety verifiable and traceable.

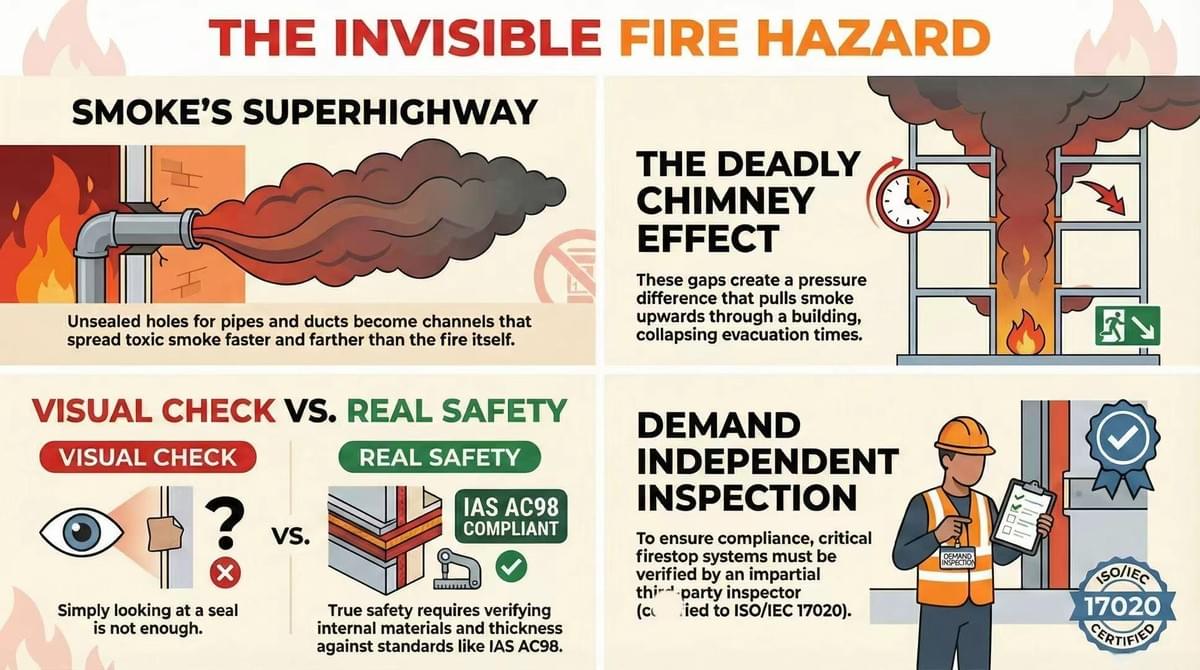

1. The Overlooked Weak Link: Smoke’s “Fast Lane”

In buildings dense with MEP and ventilation systems, countless pipes and ducts penetrate walls and floors. Without compliant firestop materials or fire-rated duct systems, these openings quickly become high-speed channels for smoke and heat during a fire.

Two lethal risks are often underestimated:

• Chimney Effect

Poorly sealed or unsealed penetrations create strong pressure differentials that pull hot, toxic smoke rapidly into other floors and zones—effectively breaking the fire compartment.

• Structural Failure

Ducts without adequate fire resistance may deform, collapse, or fall under high temperatures, opening further pathways for smoke and flames to spread.

Substandard materials, insufficient sealant thickness, or superficial “surface-only” firestopping are common on job sites. These hidden defects remain unnoticed until a fire exposes them in the worst possible way.

2. From Guesswork to Evidence: Inspection Needs a Golden Standard

Because firestop work is largely concealed, it cannot be reliably assessed by the naked eye. A verifiable, traceable inspection framework must replace quick walk-through acceptance. Two elements define this framework: who inspects, and according to what standard.

1) Credibility of the Inspector: ISO/IEC 17020

ISO/IEC 17020 sets global requirements for the competence and impartiality of inspection bodies. It ensures organizations operate independently, systematically, and professionally—forming the foundation for trustworthy inspection results.

2) Technical Rigor of the Method: IAS AC98

IAS AC98 is the internationally recognized accreditation standard specifically for firestop and fire-resistant duct inspections. It requires verification according to ASTM, UL, FM and other referenced standards, using destructive and non-destructive tests.

Critical components must be measured directly—such as mineral wool compaction, sealant thickness, and backing materials—rather than merely checking whether “the surface is covered.”

In short, compliance must be determined by standardized procedures and quantifiable data, not by visual approximation or subjective experience.

3. Why the “Referee” Cannot Also Be the “Player”

Even the best standards fail when contractors act as both installer and inspector. Contractors face pressure from cost, schedule, and acceptance deadlines, making self-inspection vulnerable to bias.

This is why global best practice requires independent third-party inspection for critical fire protection systems.

The value of independence lies in:

- No involvement in material supply or installation—removing conflict of interest

- Strict adherence to standardized sampling and measurement procedures

- Accountability to the building owner and regulators—not to construction progress

This transforms firestop work from “done equals accepted” into a traceable evidence chain:

material verification → installation records → final inspection report.

Only then does a true quality loop exist.

4. Putting Standards Into Practice: What Shanghai OKRO Provides

Shanghai OKRO Construction Technology operates under the ISO/IEC 17020 framework and specializes in independent inspection of firestop and fire-rated duct systems. We provide building owners, general contractors, and risk management teams with safety documentation that is visible, traceable, and enforceable.

Leveraging deep experience with FM, UL, and GB standards, OKRO conducts IAS AC98-aligned services including:

- Pre-construction review of material compliance and system design

- On-site destructive and non-destructive sampling with defect lists

- Bilingual (Chinese–English) technical reports

These reports support China’s fire acceptance procedures, internal compliance audits for multinational companies, and underwriting assessments conducted by international insurers.

Most importantly, OKRO exclusively serves as the referee—never a contractor or material supplier—ensuring true independence and impartiality.

5. Safety Allows No “Good Enough”

The Hung Fuk Estate tragedy and many recent building fires prove a harsh reality: once “good enough” thinking enters hidden fire protection work, the result may be irreversible loss of life and catastrophic property damage.

Passive fire protection systems—especially firestop and fire-resistant duct systems—form the last structural line of defense during a fire. To ensure these systems perform when it matters most, they must be inspected according to IAS AC98, ISO/IEC 17020, and other international standards by independent third-party professionals—not merely checked on paper or judged visually.

Shanghai OKRO Construction Technology is committed to revealing risks long before a fire occurs—exposing hidden hazards, eliminating them at the source, and making compliance visible and verifiable.